Introduction

Wafer grinding wheels are used in the in-feed grinding process of semiconductor wafers such as TSV package (Cu/compound), SiC, sapphire, Si and reclaimed wafers etc. The in-feed grinding process consists of rough and fine grinding processes. Wafer grinding wheels are made of diamond abrasives and customized vitrified bond in a unique porous microstructure. The diamond size for rough and finish grinding processes are #325~#1000 and #2000~#8000 respectively. The features of these wafer grinding wheels are stable high removal rate, long lifetime and lower grinding resistance.

Wafer Grinding Wheels

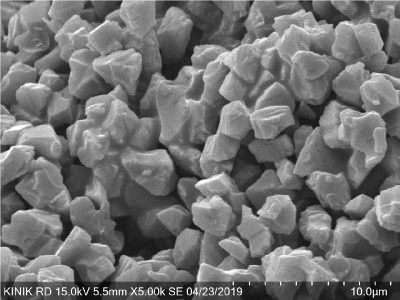

Porous microstructure

Specification

Here is a wafer fine grinding example of 8” & 12” Si wafers by #4000/#6000 wafer grinding wheels in-house and by customer. The result indicating lifetime of KINIK wafer grinding wheels with less tip wear is longer than that of competitor’s.

| Wafer | 8" Si | 12" Si | ||

|---|---|---|---|---|

| Specification | Bond | VW | VW | VW |

| Diamond# | 4000 | 6000 | 4000 | |

| Machine | DISCO_850 | DISCO_850 | DISCO_8560 | |

| Current (A) | 6~8 | 7~9 | 7~9 | |

| Tip wear (um) | 0.5~2.5 | 0.5~2 | 0.5~2 | |

| Roughness (Ra, um) | 0.023 | 0.010 | 0.022 | |

| Exxxxx-N2 | KINIK | Competitor |

|---|---|---|

| Machine | DISCO_840 | |

| Current (A) | 5~6 | 5~6 |

| Tip wear (um) | 0.3 | 0.9 |

| Roughness (Ra, um) | 0.01 | 0.01 |