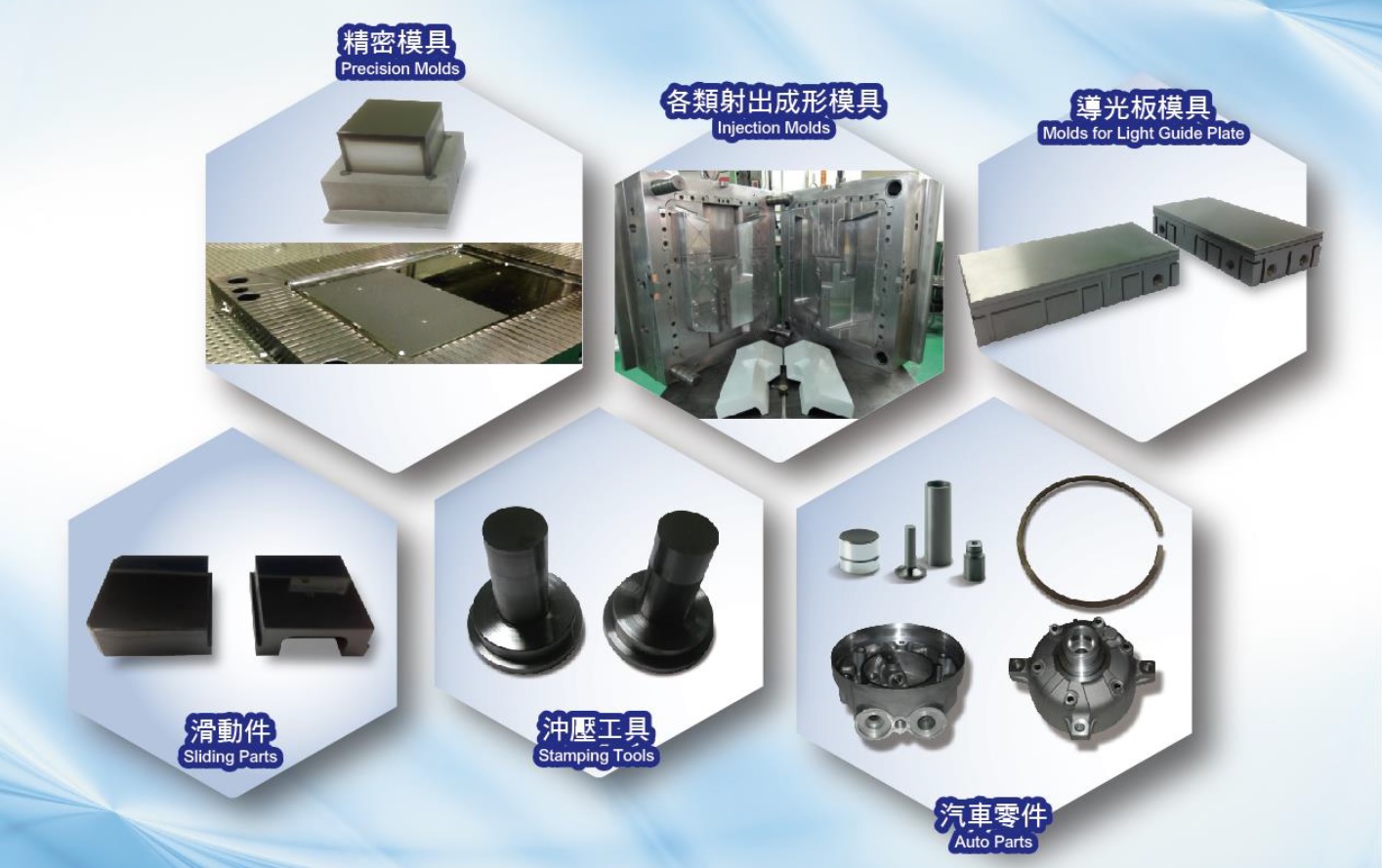

Applications

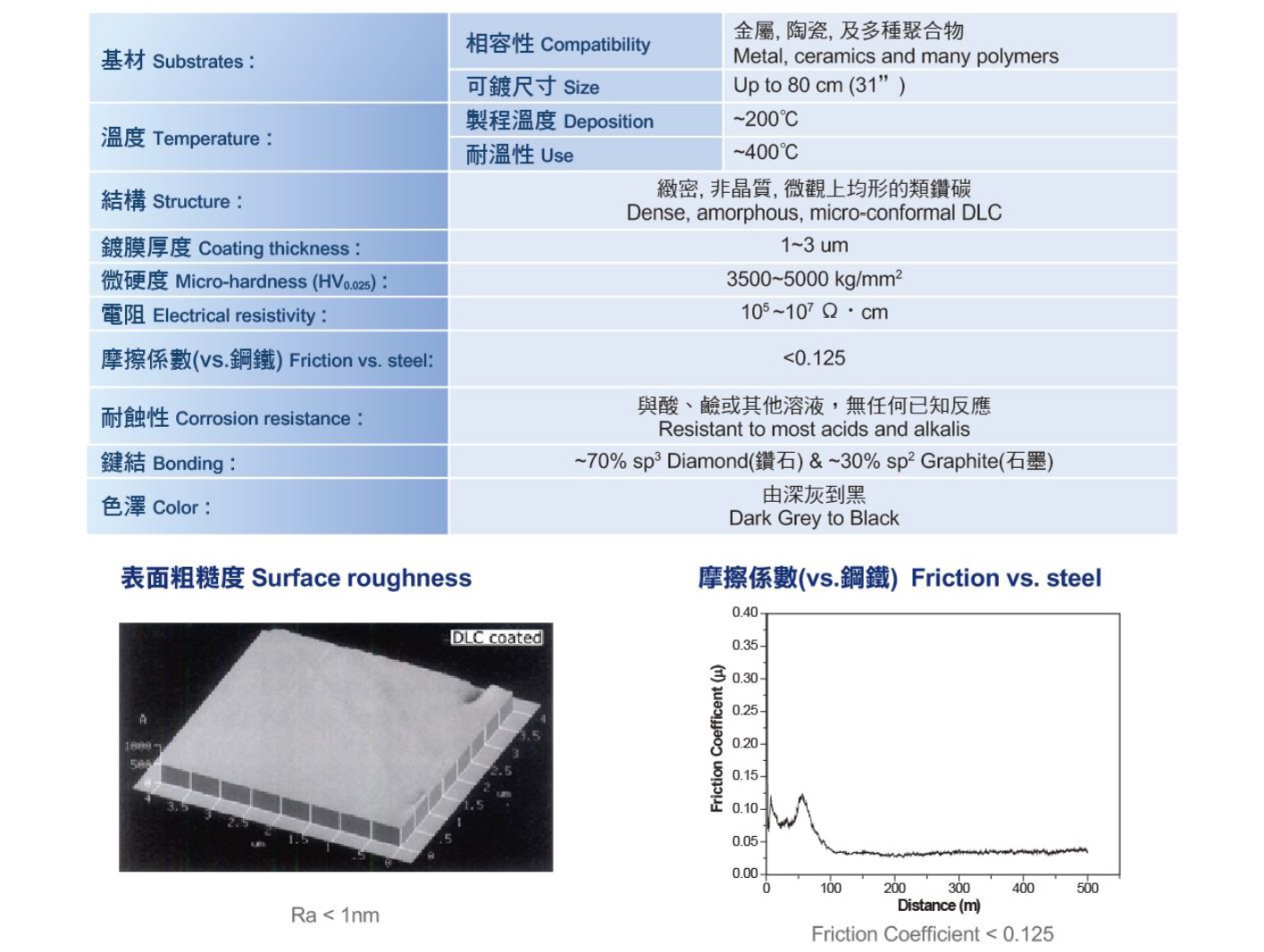

Features

- High wear resistant

- Anti-sticking

- Super hard

- Ultra low coefficient of friction

- Exceptional surface quality(Low Ra)

- Corrosion resistant

- Good insulation(~MΩ)

- Good surface flatness

Overview

DLC is deposited using a low-temperature (~200℃)proprietary Plasma Enhanced Chemical Vapor Deposition (PE-CVD) process and can be deposited on virtually all vacuum compatible substrates.

Application of DLC Coating

- Precision Molds, Injection Molds

- Moving Components, Mirror-polished Parts

- Precision Ceramic Parts

- Auto Parts

- Wear Tools, Cutting Tooling

- Medical instruments

- Diaphranm tweeter, Micro-drills, Glass, CD & DVD Mold

Specifications