All five plants of KINIK have implemented the ISO 9001:2015 quality management system and established relevant management procedures in accordance with international standards, covering raw material management, procurement standards, process management, product inspection, product anomaly handling, customer satisfaction survey, and customer complaint handling. From the pre-production raw material procurement process to the subsequent product anomaly and customer complaint handling, there is a complete management process, which serves as the compliance basis for the plant to implement quality management.

Quality culture

Our quality policy is to "meet customer needs at the most economical and effective cost" and "continue to create product value and fully win customer's praise." Continue to improve product quality and establish a quality culture amidst the daily operations through delivering quality courses, activities, quarterly reports, competitions and improvement plans.

Quality Improvement Project

To achieve sustainable business goals and improve product technology and quality performance, KINIK has promoted a multi-year lean plan, and each year each department is required to submit a self-improvement plan and report the annual goals and results.

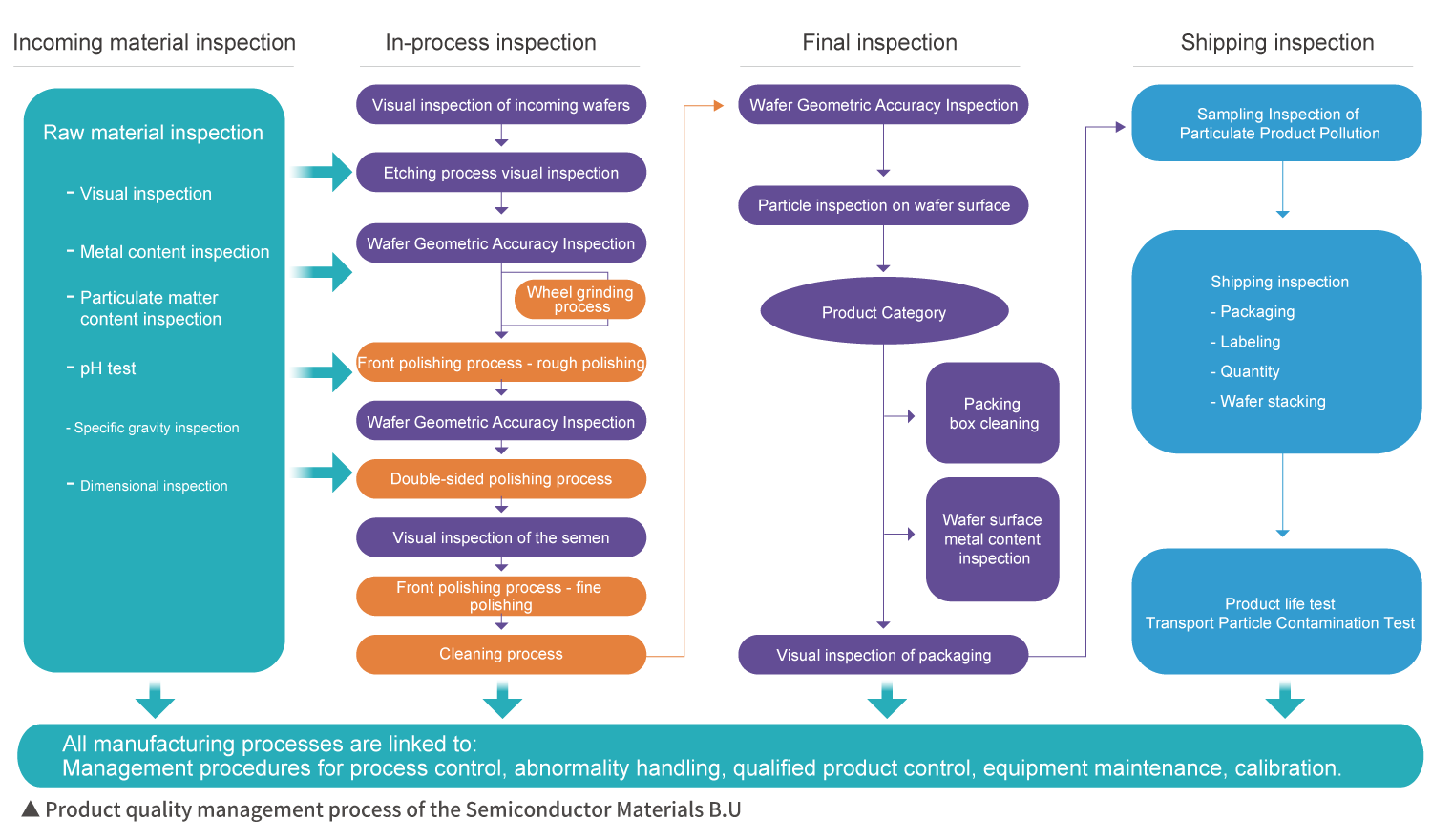

Product Quality Management

KNIIK strictly controls product quality according to the procedures of the "Quality Management Manual", and each business unit has developed a number of testing methods or procedures to control product quality.

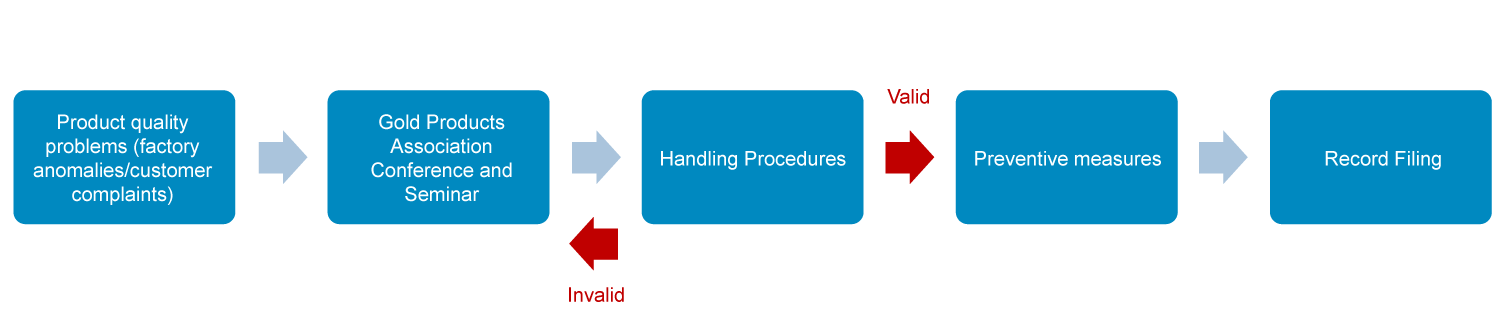

According to the "Regulations for the Establishment of Gold Products Association", the Abrasives B.U. has established a gold product association meeting system. When detecting product quality abnormalities, a meeting will be activated for immediate handling and improvement. In the event of a product doubt, we will execute the product recall procedure in accordance with the "Regulations Governing Product Returns" and the "Procedures for Control of Non-conforming Products/Materials" and hold follow-up improvement meetings. However, there were no product recall incidents in 2022.

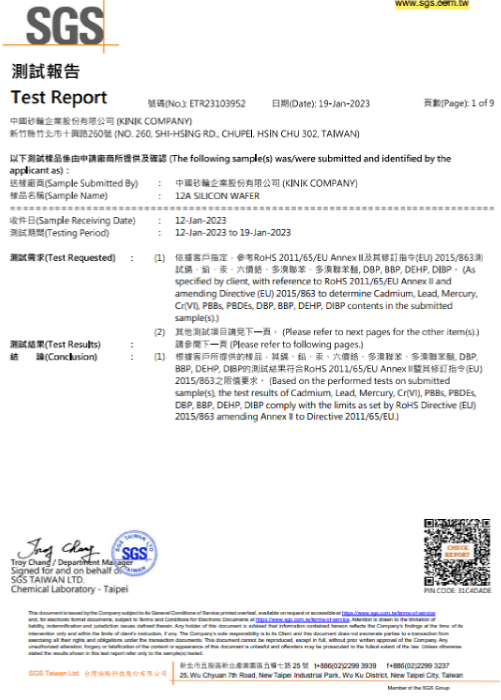

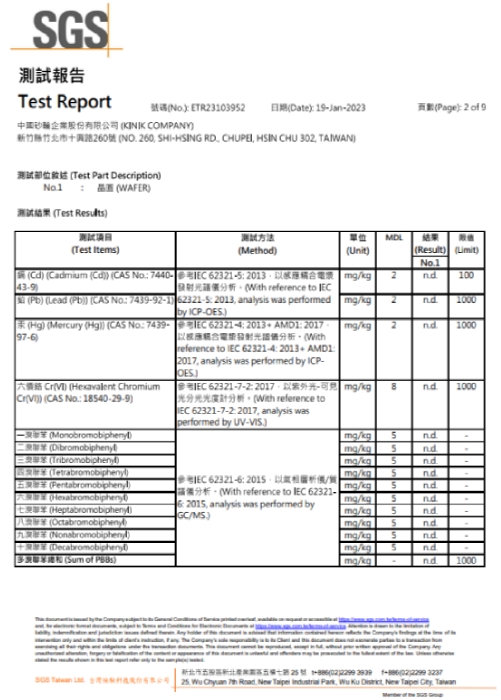

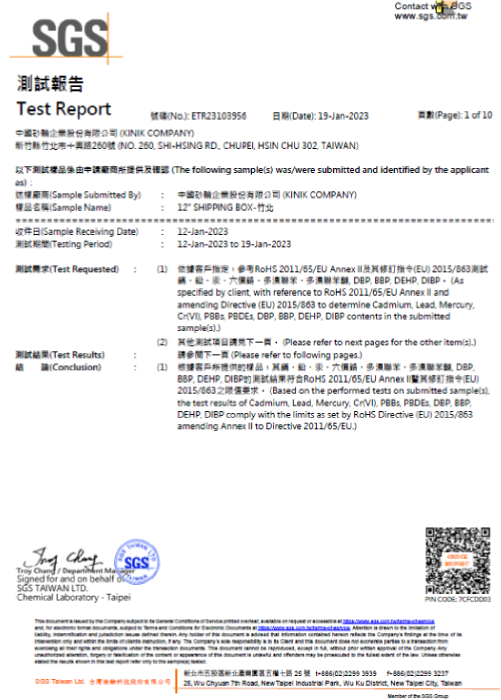

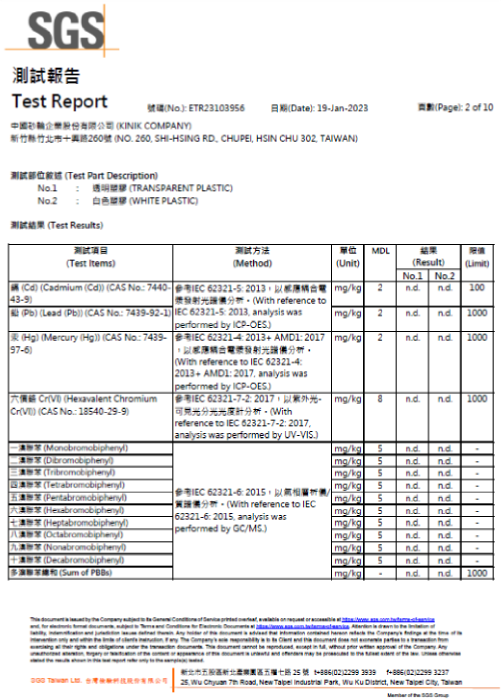

Hazardous Substance Management

All products of the 5th Plant of KINIK, Taiwan are regularly tested and managed for hazardous substances in accordance with EU-RoHS and Reach standards. The packaging materials of the reclaimed wafer products are also tested against the product standards on a regular basis. In addition to rigorous management of hazardous substances in our products and services, we also require suppliers to provide product hazardous substance test reports and sign the "Environmental Restricted Substance Non-use Declaration" to ensure that all products of the Company are free from the risks of endangering customers' health and safety.